RFH 355nm 고체 UV 레이저는 광학 유리의 레이저 절단 및 드릴링 문제를 해결합니다.

Feb 10 , 2023RFH 355nm 고체 UV 레이저는 광학 유리의 레이저 절단 및 드릴링 문제를 해결합니다.

지난 주, 광학 유리 레이저 절단 및 드릴링 공장의 한 고객이 RFH 355 시리즈 수냉식 고체 UV 레이저 배치를 주문했습니다.

오늘은 특별한 종류의 유리인 광학 유리에 대해 이야기해 보도록 하겠습니다. 광학유리는 렌즈, 프리즘, 거울, 윈도우 등 광학기기나 기계시스템의 부품을 제조하는 데 사용되는 유리 소재로 핵심 부품이다. 광학 유리의 제조 기준은 매우 엄격합니다. 굴절률 값과 같은 일부 매개변수는 설계 공차 범위 내에 있도록 엄격하게 보장되어야 합니다. 그렇지 않으면 폐기물이 됩니다. 그렇다면 이러한 고급 특수 유리는 어떻게 만들어질까요? 다음으로 RFH의 말을 잘 들어보세요.

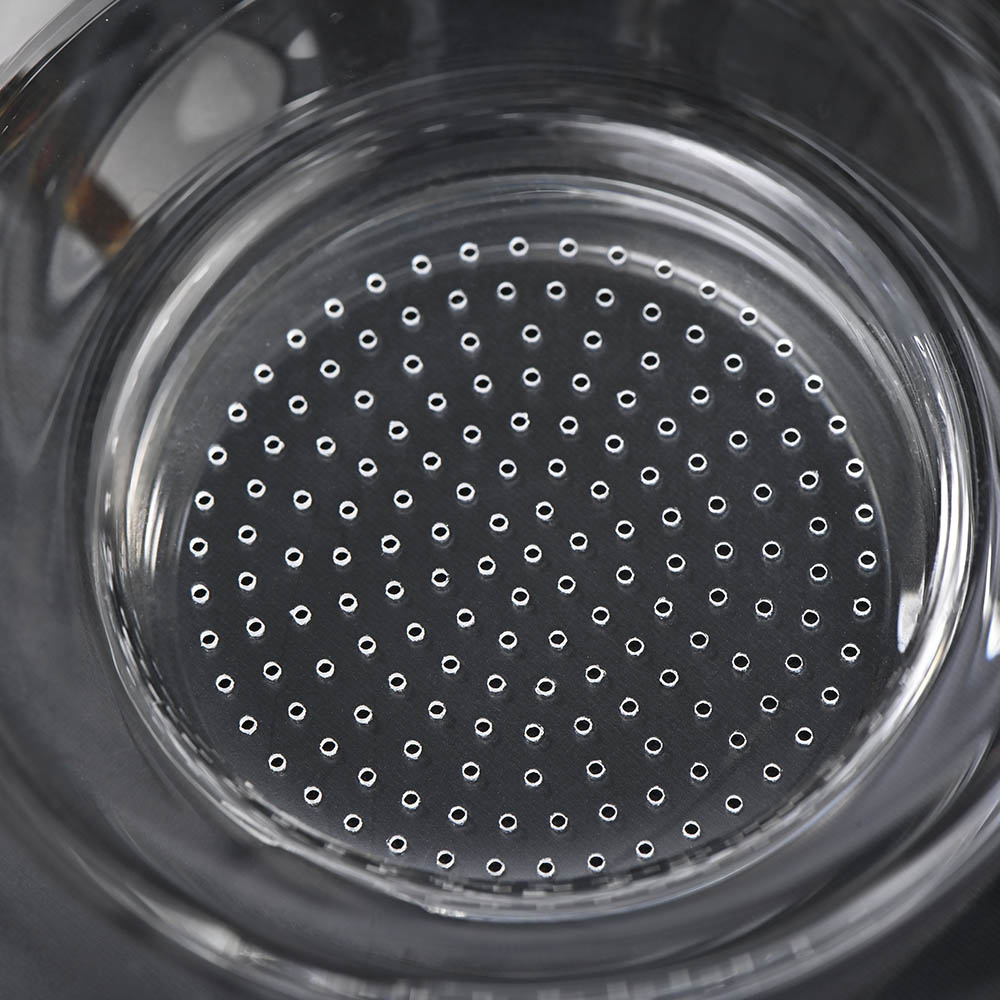

고체 상태 355nm 자외선 레이저 드릴링 유리

First of all, the raw materials of optical glass mass-produced in the general industry are all in one piece. It needs to be cut, punched, etc. according to the shape requirements of the design first, and then finished and coated. So how are these thin and brittle glasses cut? At first, the precision CNC spindle cutter was used for cutting, but the quality was difficult to control, and the yield rate was far below the expected value. Later, more sophisticated lasers came out, which solved the problem and realized batch processing.

3d glass etching with UV laser cold source

At present, there are two main types of lasers used in optical glass cutting and drilling, ultraviolet lasers and green lasers. Next, take a laser cutting machine that uses our RFH 355 series water-cooled Solid State UV laser as an example to explain why Solid State UV laser cutting machines can become mainstream optical glass cutting and drilling processing equipment.

1. This 355 series water-cooled ultraviolet laser has a laser wavelength of 354.7nm, a wide repetition rate coverage (single pulse to 200kHz), excellent beam quality (M2<1.2), and is strictly guaranteed in all frequency ranges; pulse The width is <16ns@40k, and the heat-affected zone is very small during processing. Such laser beam quality can ensure the processing quality of optical glass: narrow incision, smooth cutting edge, small edge chipping, and fast processing speed, which is suitable for enterprises to carry out mass production. Processing and production; 2. It has a unique Q-switching control technology, which is suitable for various laser application control requirements; it contains online refresh harmonic control technology, and the power stability time is super long, so you don’t have to worry about performance degradation after a period of time. This is also the choice of many manufacturers. One reason to use our laser; 3. Will it be difficult to operate such a precise laser? Not so, in fact its operation is very simple, it supports communication with the computer, and the laser can be controlled externally through RS232; at the same time, it adopts all-digital intelligent power control technology, and the monitoring is also very convenient.

How did RFH make such a first-class quality laser? This is about our R&D team and production management system. RFH has a top-level laser research and development team composed of professors and doctors from Tsinghua University, and has set up application process research and development departments, laser research and development departments, and electrical research and development departments, which are the solid backing for the stable operation of RFH's entire laser system; Management system, we have invested a huge amount of money to build a full-process dust-free production workshop, and the quality control department strictly controls the incoming materials, production, machine acceptance, and shipment to ensure product performance and quality. Because of this, RFH has won high recognition and a good reputation from users from all walks of life at home and abroad.

After 16years of hard work, RFH Laser has established an excellent brand image in the nanosecond laser industry.