유리 강화 PCB 재료의 UV-YAG 레이저 드릴링

Nov 22 , 2021UV-YAG laser drilling of glass-reinforced PCB material

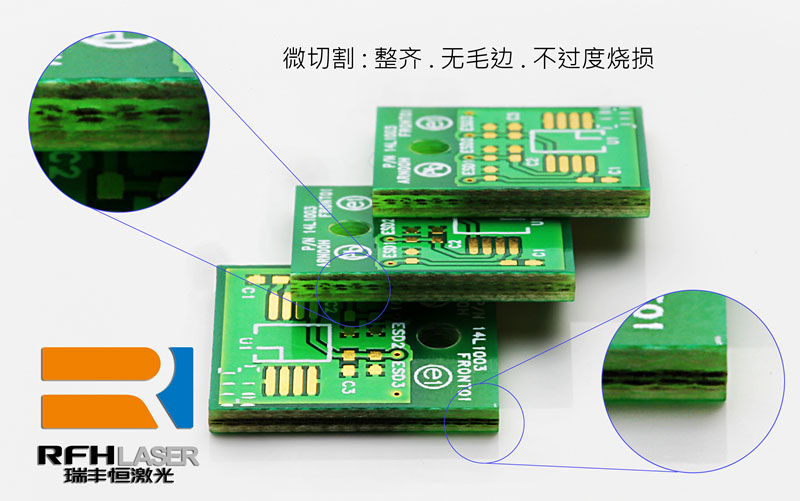

The miniaturization of electronic products for information and communication has led to the increase of circuit density of PCBs. This means that the holes which connect the isolated circuit layers in multilayer PCB are downsizing. CO2 and Nd:YAG laser operated at infrared wavelength of 10.6 mm and 1.06 mm are used extensively to fabricate microvias in PCB fabrication. However, the major drawback of laser drilling GFRP materials is the existence of heat-affected zone (HAZ) which are formed around the laser-drilled holes. This is because the material-removal mechanism with infrared lasers is a thermal mechanism (melting, evaporation, or vaporization). The differences in temperatures of vaporization and decomposition between glass fibres and epoxy resin in GFRP materials result in the presence of HAZ, which always show itself as recession and decomposition of matrix material. One of the most important methods to reduce the thermal effects is to use UV lasers in drilling microvias. The high energy UV photons can directly atomize material in a process known as photo-ablation.

자외선 레이저 | 녹색 레이저 | 자외선 레이저 | 자외선 dpss 레이저 | 나노초 레이저 | UV 레이저 소스 | 고체 레이저

유리 섬유 강화 플라스틱(GFRP) 인쇄 회로 기판에 UV YAG 레이저 천공 구멍의 열영향부(HAZ) 특성을 조사합니다.

다양한 레이저 파라미터에 의해 생성된 HAZ의 구조가 시연되었습니다.

HAZ의 형성 메커니즘 이해

섬유 강화 복합재에서 HAZ의 크기를 평가하고 검증하기 위해