산업용 피코초 레이저로 유리 조각 및 절단

Dec 07 , 2022산업용 피코초 레이저로 유리 조각 및 절단

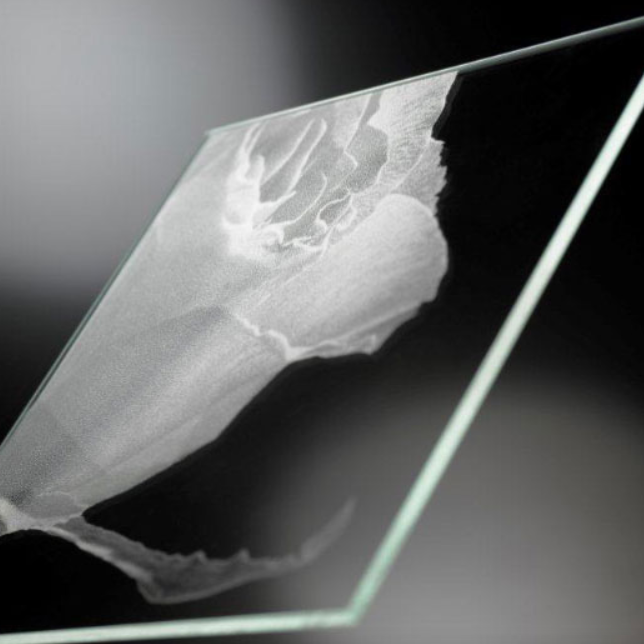

Glass is a material commonly used in micromachining and precision machining, and is widely used in consumer electronics, automobiles, optical lenses, home appliances and other fields. Nowadays, as the market has higher and higher requirements for the precision of glass materials, it is necessary to achieve higher precision processing effects. The remarkable feature of glass is its hardness and brittleness. Whether it is a diamond knife, an alloy knife or a water knife, this kind of traditional processing technology has some disadvantages, which cannot meet the special-shaped processing of glass products and the control requirements for edge quality and fine cracks.

With the continuous development of picosecond laser technology, the use of infrared picosecond lasers for precision processing of glass has become a reliable choice. To this end, Nafei Optoelectronics has developed an industrial-grade picosecond laser, which is suitable for precision processing of glass products.

Picosecond laser processing glass principle

When the laser is focused by the focusing head, a micron-sized beam with huge single pulse energy and high peak power and high power density is obtained. When the beam acts on the glass material, the light intensity at the center of the beam is lower than that at the edge, and the refractive index at the center of the material is larger than that at the edge. , the propagation speed of the center of the beam is slower than that of the edge, and the beam has a nonlinear optical Kerr effect to generate self-focusing, and the power density continues to increase. When a certain energy threshold is reached, the electrons are detached from the shackles of the atoms to form a plasma.

Due to the extremely short interaction time between the laser and the material (pulse width <10 ps), the plasma has been ablated from the glass surface before it can transfer energy to the surrounding materials, and there is almost no heat-affected zone and no obvious small cracks Or surface debris, which ensures that the surrounding materials in the space involved will not be affected during the processing. This process is often called "cold processing", which greatly improves the processing quality.

It can be seen that the non-contact laser processing not only saves the cost of mold development, but also avoids the problems of edge chipping and cracks caused by traditional cutting methods. Processing can effectively improve the efficiency of production operations and the yield rate of finished products, and promote users to reduce costs and increase efficiency.

In addition to the above advantages, industrial-grade picosecond lasers can be configured with different repetition rates according to different application requirements. The repetition rate is adjustable from 100KHz to 2MHz and has a Burst mode. With an output power of up to 30W, beam quality M2<1.3, and power stability (RMS)<1%, it is a magic weapon that meets the precision processing and production of glass products in large quantities.